Industrial Upgrade: Advancing Existing Industries for a Smarter Future

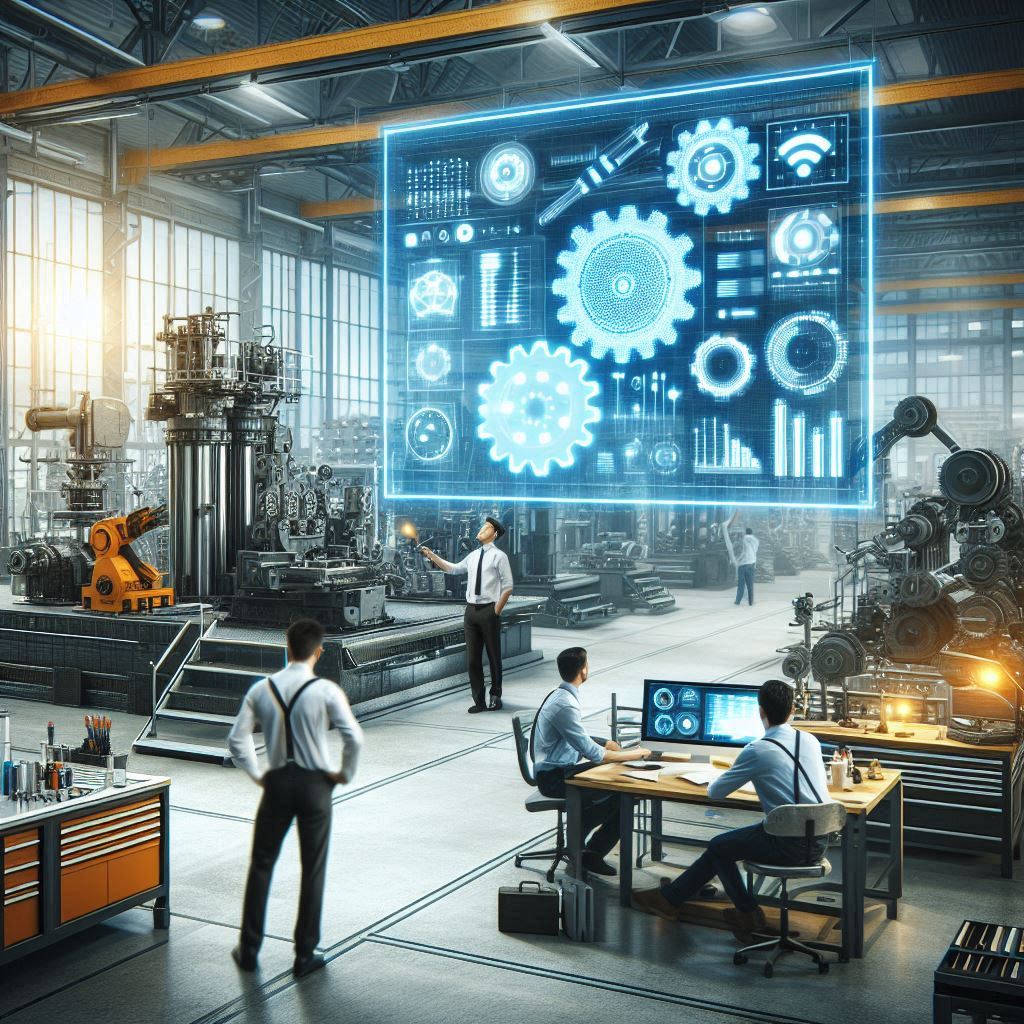

Industries across the globe are witnessing a rapid transformation, driven by technological advancements and evolving market demands. This industrial upgrade—often associated with modernization, automation, and digital integration—is reshaping how businesses operate, making them more efficient, sustainable, and adaptable to future challenges.

The Need for Industrial Upgrades

As competition intensifies and consumer expectations rise, industries must evolve to remain relevant. Outdated machinery, legacy processes, and manual workflows can hinder productivity and lead to inefficiencies. The upgrade process includes the integration of Industry 4.0 technologies, such as artificial intelligence, Internet of Things (IoT), automation, cloud computing, and data-driven analytics, to optimize operations and improve output quality.

Key Advancements in Industrial Upgrades

Automation & AI Integration Robotics, machine learning, and AI-powered systems streamline manufacturing, minimize errors, and improve production efficiency.

Smart Sensors & IoT Connectivity IoT sensors enable real-time monitoring of machinery, predictive maintenance, and enhanced resource allocation, reducing downtime.

Sustainable Energy Solutions Upgraded industries are adopting eco-friendly practices, such as energy-efficient equipment, green manufacturing techniques, and reduced carbon footprints.

Advanced Supply Chain Management Cloud-based logistics and AI-driven inventory tracking enhance transparency and reduce bottlenecks in supply chains.

Cybersecurity Enhancements As industries become more interconnected, robust cybersecurity measures ensure data integrity and protect against cyber threats.

Applicability in Today’s Industries

In manufacturing, smart factories powered by automation and IoT are revolutionizing assembly lines. The automotive sector is transitioning to electric mobility and AI-driven vehicle diagnostics. Healthcare industries are leveraging robotic-assisted surgeries and AI-based diagnostics for better patient care. Even traditional businesses, such as agriculture, are adopting precision farming techniques powered by AI and data analytics.

Future Outcomes of Industrial Upgrades

The future holds exciting possibilities as industries continue evolving. Hyper-automation, 5G-powered industrial connectivity, and quantum computing advancements will further optimize operations, leading to self-sustaining, autonomous systems that require minimal human intervention. Sustainable innovation will drive greener production methods, reducing environmental impact and fostering global efforts toward a circular economy.

Impact on Workforce & Potential Replacement

Industrial upgrades do not necessarily mean complete job displacement; rather, they create new opportunities for skilled workforce training and technological adaptation. The shift towards automation will redefine job roles, with employees focusing on overseeing, programming, and maintaining intelligent systems instead of performing repetitive manual tasks. Governments and industries must invest in reskilling programs to ensure a smooth transition for workers into technology-driven roles.